Why the Sealant Didn’t Stick?

Today, I got an urgent call from a customer: “Your sealant doesn’t work, there’s a problem. Yesterday I had to rework a piece of insulated glass. When I tried to open the unit (separate the panes), I just gave it a gentle pull and the whole sealant strip came off easily — it didn’t stick to the glass or the spacer at all. You’d better come to the site and take a look.”

The first thing that came to my mind: sealant curing.

After more than a decade in the sealant industry, I know that problems like this almost always point to one thing — incomplete deep curing of a two-component silicone sealant. In this article, I’ll break down the curing process and explain how to ensure a strong, lasting bond.

Sealant Curing is a process — not just a matter of time.

Many people wonder, “How long does it take for two-component silicone sealant to cure?” The truth is, there’s no single number of hours that tells the whole story. Curing isn’t an instant switch—it’s a gradual process. Understanding it this way helps set realistic expectations and ensures the best results.

1. Surface curing

Surface curing, which in our terminology is called surface tack-free, is usually completed within 1–2 hours. The concept of surface curing is that the surface of the sealant has already formed a skin. When we gently touch it with a finger or a toothpick, the sealant will not pull out a thin thread. Generally speaking, after surface curing is completed, it is not suitable to adjust the product’s appearance anymore. If you forcibly adjust it, the surface of the sealant will appear granular, and it will not be smooth and glossy.

2. Deep curing

Deep curing is the time when the inside of the sealant is completely cured. The deep curing time of two-component sealant generally requires 2–3 days.

The inside of the sealant needs time to react.

Why does surface curing only need one hour, while deep curing requires two or three days? This is because two-component silicone sealant belongs to room-temperature vulcanized silicone rubber. The crosslinking agent in Part B needs to absorb moisture in the air to undergo hydrolysis reaction to generate silanol. After hydrolysis, the crosslinking agent reacts with the silanol on the 107 silicone rubber in Part A through a condensation reaction to achieve a three-dimensional network crosslinking structure.

In addition, as the condensation reaction proceeds from the surface to the inside, the speed of water vapor from the outside air penetrating into the sealant becomes slower and slower. This is the reason why deep curing is much slower than surface curing.

Back to the customer’s case

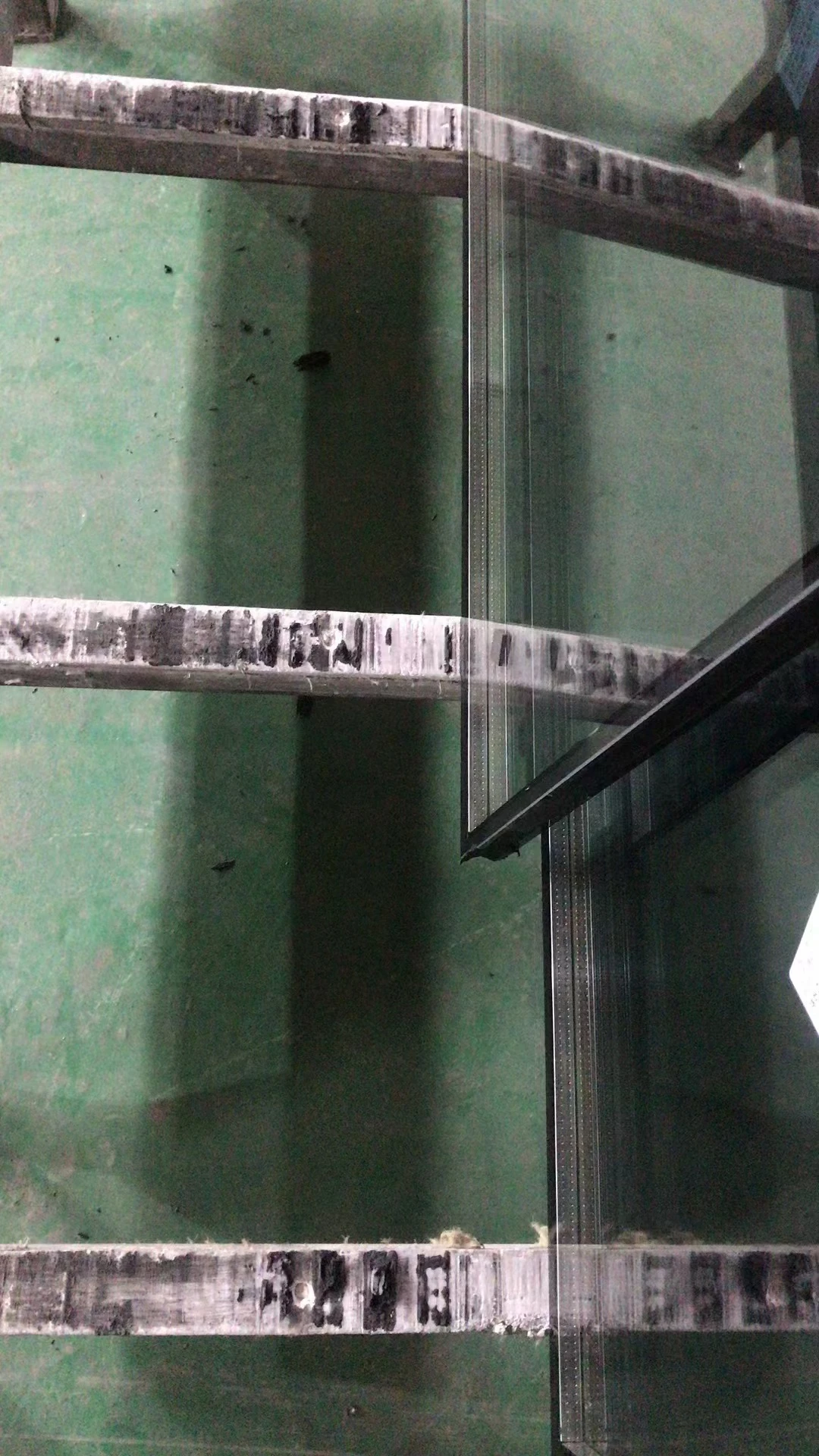

The customer said that the sealant strip fell off with a light pull, and in fact this is a typical manifestation of incomplete deep curing. The entire sealant strip bonded poorly with the glass and the spacer, and it was easy to pull off. This is exactly the problem presented when the sealant has not achieved deep curing. Because after the insulated glass is sealed, it is placed on wooden strips of the rack. The wooden strips are loose and porous substrates that easily adhere. The surface sealant in close contact with the wooden strips quickly cures, while the sealant in contact with glass and spacer needs to complete deep curing to have excellent adhesion. Before deep curing is completed, the adhesion force between the sealant strip and the wooden strips is greater than that with the glass and spacer. At this time, when the insulated glass is moved away from the wooden rack, it may cause the sealant to detach from the glass and spacer, but still firmly stick to the wooden strips.

How to judge whether it is truly “cured”?

The most accurate determination of whether the sealant has completed deep curing is tested in laboratory equipment for its strength, elasticity, stability, etc. However, for construction sites and factories, this is often impractical. In light of this, we offer a feasible suggestion for the sealant installation factories: when you need a relatively accurate deep curing time, please find a sample glass in your construction site, put the used product in the same environment, and after 24 hours and 48 hours, you can cut open the sealant to see the inside condition. If the inside is still soft, sticky, or the color is inconsistent between inside and outside, it means deep curing has not been completed. Remember not to use a single touch to determine whether deep curing has been completed.

Factors affecting curing

There are many factors affecting the curing of two-component silicone sealant, including: the total amount of hydroxyl in Part A 107 silicone rubber, the moisture content of Part A, the total mol amount of hydrolyzable alkoxy groups in the crosslinking agent and coupling agent in Part B, the amount of catalyst added in Part B, as well as the mixing ratio of the two components, ambient temperature and humidity, etc.:

- a. The curing speed of two-component silicone sealant is mainly determined by Part B. The activity and amount of catalyst is the key to determining the reaction speed of Part B. Generally, the adjustment of curing speed of two-component silicone sealant is mainly achieved by adjusting the amount of catalyst.

- b. Secondly, the curing time is also affected by external environment, including temperature, humidity, and the thickness of the sealant we apply. Application factories and project sites cannot provide an ideal environment and cannot, like our Weidu laboratory, maintain temperature and humidity within optimal ranges. Therefore, as a silicone sealant manufacturer, what we can provide is the standard curing time under standard temperature and humidity, assuming normal application thickness.

Final reminder

For construction factories, my suggestion is very simple:

In order to ensure deep curing of the sealant, it is first necessary to give it enough reaction time. 48 hours, I think, is very necessary. Of course, if your project is in a special climate or the construction site requires accelerated deep curing, please feel free to contact us. We will adjust the product formulation system according to your situation and provide you with some customized services.

Here, I’d like to highlight one point: considering the temperature and humidity in the Middle East, application thickness, and workers’ operating habits, Weidu has carried out extensive research, collected feedback, and conducted practical tests to ensure our sealant performs optimally in this region.