This article offers valuable insights to help you identify high quality silicone sealant using the IET process. We will guide you through reading the packaging to find key technical indices, evaluating the quality through visual, olfactory, and tactile senses, and introducing an easy-to-perform silicone sealant test. It serves as a buyer’s guide to navigate the variety of sealants available on the market.

Table of Contents

ToggleA Buyer's Guide for High Quality Silicone Sealant

Sealants may not always get the attention they deserve in the building industry, but it acts as the silent guardian, safeguarding the safety and longevity of structures. Its impact on the quality of our living environment and the durability of buildings is undeniable.

That is why sealants are actually easy to find in any market. However, if you visit building material markets or search online, you will see that the market offers a wide variety of sealants, ranging from single-component, two-component, acidic, neutral, silicone-based, to both high-priced and low-priced options. How can one choose a sealant that performs well during and after construction, with strong adhesion and reasonable pricing?

What is Silicone Sealant?

Let us first understand what silicone sealant is . Silicone sealant is a chemical compound that, through the chemical reaction of various substances, forms strong, flexible bonds. It uses polydimethylsiloxane(PDMS) as the primary raw material, mixed with crosslinker, fillers, coupling agents, and catalysts, to create a paste under vacuum. At room temperature, it cures by reacting with moisture in the air to form elastic silicone rubber-like seal.

Silicone sealants are divided into two types based on its composition form: single-component and double-component. One-component silicone sealant is similar to an ointment and can be cured when exposed to moisture in the air; two-component silicone sealant requires mixing the base glue and curing agent in a proportion and then curing.

How to identify High Quality Silicone Sealant?

When it comes to identifying the quality of silicone sealant, it’s wise to consult industry experts. Bella, the Managing Director from WD Sealant has worked in the industry for a decade, and her husband Mr. He is a senior engineer who graduated from the chemistry department at Nankai University, one of China’s top universities. She recommends the IET process, which stands for package Inspection, sensory Evaluation, and quality Testing, to ensure the silicone sealant’s quality.

"I"—Package Inspection

When you are in the market to compare silicone sealant, the first step is to check the quality from its packaging. Here is how to read the labelling and instruction from a silicone sealant.

Standards

The performance and quality of silicone sealant can often be glimpsed through the standards listed on its packaging. By learning to interpret this information, you can easily select high-quality products.

GB/T 14683-2017 Silicone and Modified Silicone Building Sealants: If it is labelled with this standard, the product is suitable for general decoration and non-structural assembly of building curtain walls, as well as for modified silicone building sealants used in building joints and dry shrinkage displacement waterproofing projects.

- F Class – For building joint applications.

- Gn Class – For general decorative and decorative glass installation, not suitable for insulated glass.

- Gw Class – For non-structural assembly in building curtain walls, not suitable for insulated glass.

.If you scan the package QR code, it provides more detailed information, such as for WD-886, where the packaging specifies GB/T 14683-GW-35HM.

It follows the GB/T 14683 standard, specifically the GW class. This indicates that the product is suitable for use with doors, windows, skylights, curtain wall glass, stone, and aluminum panels, but is not recommended for insulated glass.

- The “35HM” in GB/T 14683-GW-35HM refers to a high-modulus grade, indicating that the material demonstrates a 35% displacement and successfully meets performance requirements after undergoing repeated tensile and compression fatigue testing.

| Identify Sealant Quality by Their Conformed Standards | |||

| Product | TDS Standard | What is Required by the Standard | Key Index |

| GB/T 29755-2013 | 20%HM: 20% High Module | ||

| WD-831 | GB/T 29755-2G-20HM | GB/T 29755-2013 applies to elastic sealants for insulating glass, specifying performance, testing, and durability requirements. | |

| GB 16776-2005 | MG Metal & Glass,2: Double-component,1: Single-component | ||

| WD-981 | GB 16776-2MG | The GB 16776-2005 standard applies to silicone sealants used in construction, covering performance, testing, and applications such as glazing, curtain walls, and weatherproofing. | |

| WD-986 | GB 16776-1MG | ||

| GB/T 14683-2017 | HM: High Module | ||

| The GB/T 14683-2017 standard applies to silicone sealants for construction, specifying requirements for performance, testing, and application in building joints, curtain walls, glazing, and weatherproofing.. | |||

| WD-886 | GB/T 14683-GW-35HM | G Class-For non-structural assembly in building curtain walls, not suitable for insulated glass. | 35% |

| WD-166 | GB/T 14683-F-25HM | F Class – For building joint applications | 25% |

| WD-866 | GB/T 14683-F-25HM | 25% | |

| WD-GP | GB/T 14683-F-25HM | 25% | |

| WD-188 | GB/T 14683-F-25HM | 25% | |

| WD-836 | GB/T 14683-F-20HM | 20% | |

| WD-136 | GB/T 14683-F-20HM | 20% | |

| HM high module represents how much the sealant can handle displacement, tension , and compression forces without significant deformation | |||

We have listed the products and the standards they conform to, which are mass-produced at the Weidu factory. However, we can also customize products to meet other standards, such as GB/T 23261-2009 for stone and JC/T 885-2016 for mold resistance.

- GB/T 23261-2009: The packaging label bearing this standard indicates that the product is specifically designed for stone, protecting it from corrosion and extending its service life.

- The JC/T 885-2016: The packaging label meets the standard that applies to mold-resistant sealants used in construction. It sets performance, testing, and quality control requirements to ensure the sealants are effective in preventing mold and mildew in moist environments.

SGS & TDS

In addition to the standards, the SGS and TDS files offer crucial information regarding quality.

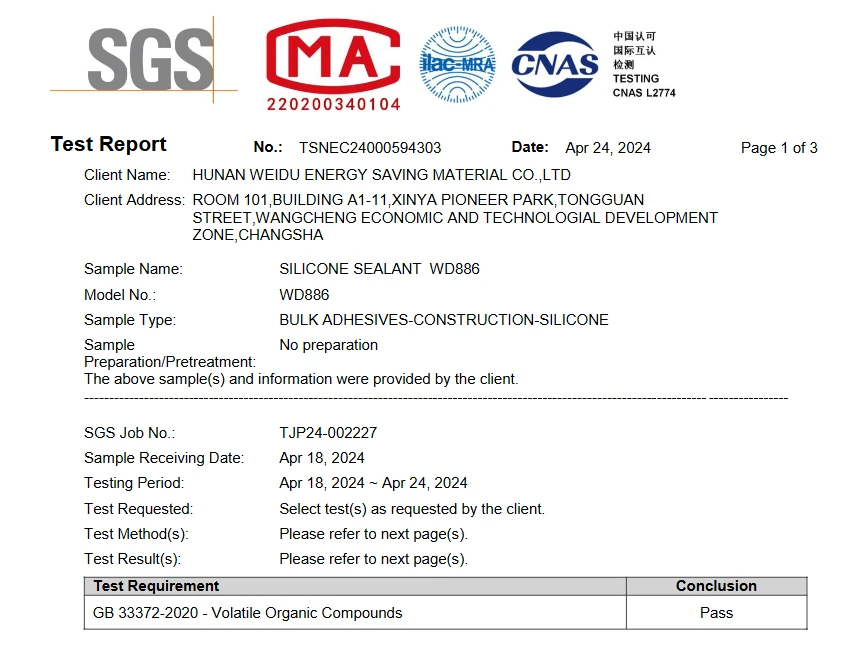

For example, the SGS report above provides comprehensive details about a sample of “SILICONE SEALANT WD886” from Hunan Weidu Energy Saving Material Co., Ltd., based in Changsha, China. It includes the sample’s model number (WD886), type (bulk adhesives for construction), and the date it was received (April 18, 2024). The report highlights that the test conducted was for volatile organic compounds (GB 33372-2020), with testing carried out from April 18 to April 24, 2024. The conclusion confirms that the silicone sealant passed the required test.

The TDS report provides additional detailed information, including the product description, features, and typical properties both in the uncured and cured states. It also covers important aspects such as surface preparation, cleaning procedures, masking, primers, tooling, and finishing. All the information available on the package is thoroughly listed and explained in the report.

Other Information

In addition to the standards, SGS, and TDS reports, which contain all the technical information, it is recommended to review the company’s website for further details about the factory producing the sealant. This provides a broader understanding of the manufacturer and their operations.

"E"—Sensory Evaluation

Sensory evaluation involves checking the sealant’s quality by looking (observing with the eyes), smelling (using the nose), and touching (using the hands).

Step 1: Observe Glossiness

First, we can assess the glossiness of the sealant. Sealants of varying quality will show noticeable differences in gloss. Lower-quality sealants often have little to no gloss, or a poor gloss that may fade within one to two months after curing. In contrast, high quality silicone sealant maintain a consistent, glossy finish even over time, without easily losing their shine.

Step 2: Smell the Sealant

Second, we can smell the scent of the sealant. Acidic sealants contain acetic acid, which produces an acidic odor during the volatilization process. Generally speaking, the higher the quality of the sealant, the lighter the acidic smell, while lower-quality sealants have a stronger acetic odor. High-quality sealants tend to volatilize quickly, whereas inferior sealants not only have a stronger odor but also take longer to dissipate.

Step 3: Check the Texture

Third, pay attention to the texture of the sealant. After curing, high-quality sealants have a fine, even, and smooth surface with no noticeable roughness. In contrast, inferior sealants may contain visible impurities and particles, and the surface is often uneven and rough.

Step 4: Inspect for Air Bubbles

Check for air bubbles when dispensing the sealant. High quality silicone sealants are 100% silicone and will not produce air bubbles when applied. Inferior silicone sealants may contain additional additives, which can cause air bubbles during application. The main ingredient in silicone sealants is silicone, and high-quality silicone sealants contain fewer additives. Pure silicone sealants have good stability, and external factors have less impact on their performance, so air bubbles do not occur during application.

Step 5: Test Softness and Hardness

Check the softness and hardness after curing. The sealant’s curing time and its softness and hardness after curing should be considered. If the curing time is too long or too short, it indicates poor quality. The proper curing time should be determined based on the actual usage environment. Additionally, after curing, the sealant can be pressed by hand; if it’s too soft or too hard, it is not a quality sealant. Another test is to cut open the cured sealant to check if the curing degree is consistent both inside and outside.

"T"—Quality Testing

While there are various methods to test quality, this article will focus on one simple and effective test for insulating glass sealant—the butterfly test.

In our factory, testing is a routine procedure to ensure the high quality silicone sealant. Since we use a two-component sealant for insulating glass, which involves both Component A and Component B, it’s crucial that they are mixed evenly to ensure optimal performance. To verify proper mixing and assess the quality of the structural sealant, we use the butterfly test on-site.

Purpose of Butterfly Test

The butterfly test checks the mixing ratio of the base adhesive and curing agent in a two-component silicone structural sealant. It ensures that the two components are thoroughly mixed. If the mixture is uneven, it can significantly affect the product’s performance, impacting the final result.

Test Method

- Fold a piece of paper in half lengthwise, creating a crease down the center.

- Mix Component A and Component B before the test, and then squeeze the sealant evenly onto both sides of the crease. Create a 20mm diameter and 15mm thick sealant pile.

- Fold the paper along the crease, dividing the sealant into two parts.

- Press the sealant pile until it is 3-4mm thick. Then, unfold the paper. The sealant should form a butterfly shape.

- Observe the sealant. If there are any white spots or streaks, it indicates that the structural sealant has not been properly mixed. In this case, injection should be postponed until the mixture is uniform in color and fully blended

Once thoroughly mixed, the white adhesive will cure properly, and the black adhesive will not powder. This ensures that the sealant’s airtightness, water resistance, shear strength, and weather resistance are all maintained at optimal levels.